Product overview

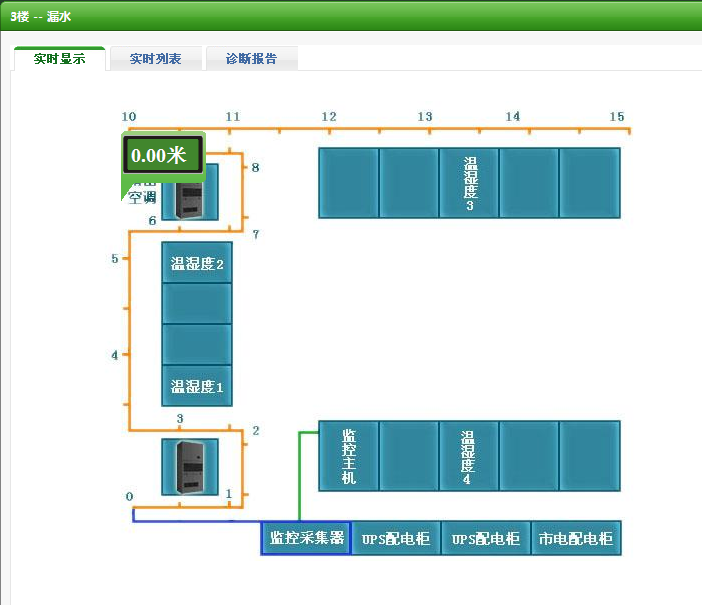

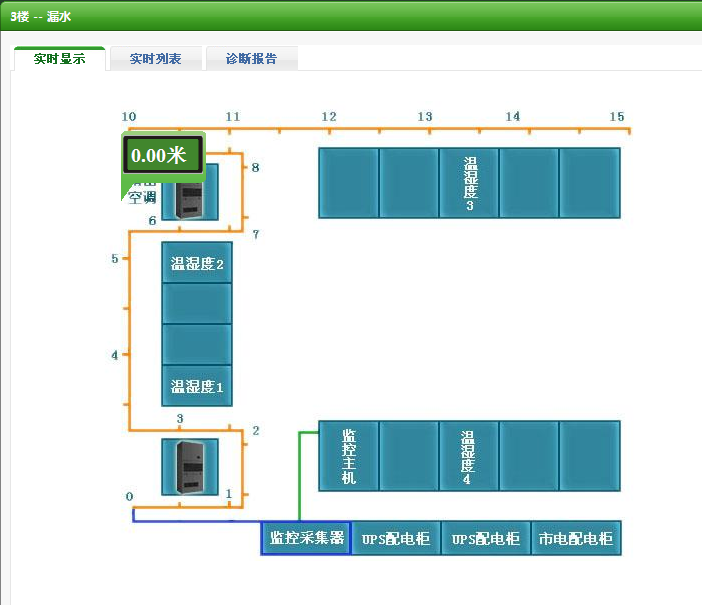

HW-2000N locating leakage detector equipment is mainly used to detect whether there is leakage in the protected area. The original double-source rotating inspection algorithm can accurately locate the leakage. It locates the leakage level by detecting the leakage detection rope laid in advance in the protected area, and can give an acoustic and optical alarm. At the same time, it can control a switch signal and play a joint role. HW-2000N has RS485 communication port, which can be connected with computer. It can be matched with company positioning leak software. It can automatically locate the leak position on the CAD map, and can be monitored remotely through the network and alarmed by mail.

Product characteristics

1) Small size, beautiful appearance;

2) Accurate positioning: The original double-source wheel inspection algorithm can accurately locate, and the positioning error is within (±0.2m).

3) Energy-saving: energy-saving and environmental protection, simplified wiring structure;

4) Simplicity: easy to install, easy to use, can be used alone;

5) Intuitivity: LCD display screen can directly display the leak location, intuitive information, easy to operate keys;

6) Extensibility: RS485 interface can be used for remote network management or stand-alone.

7) Stability: It can work continuously 24 hours a year without special maintenance.

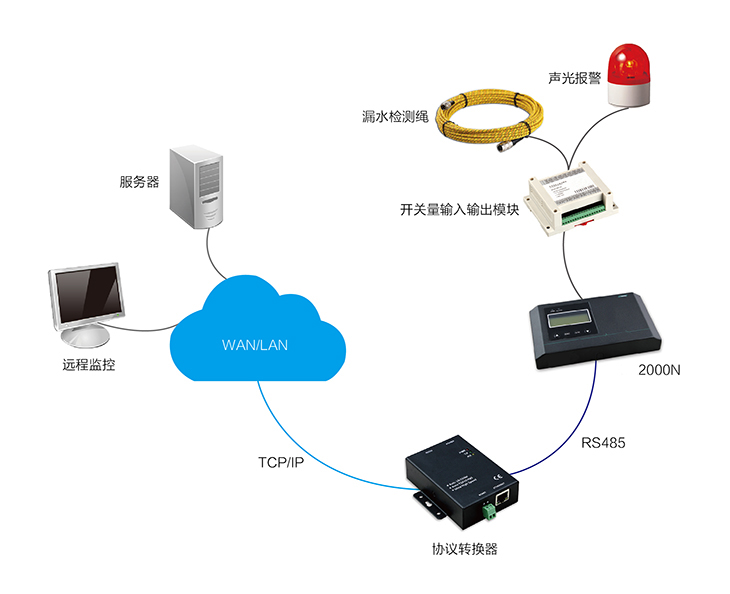

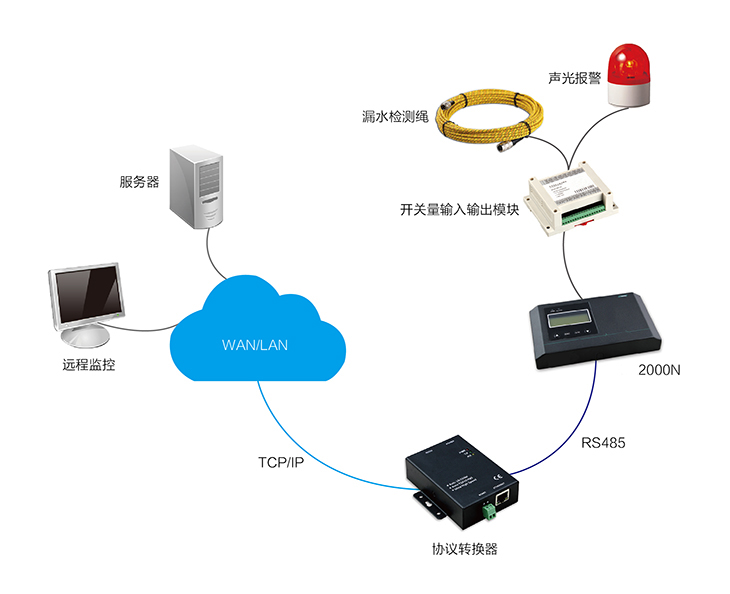

Drawing of Leakage Monitoring System

Location type leakage rope interface: with a dedicated location leakage induction rope, the longest can be allocated 300M, the accuracy error of leakage location is within (±0.2m).

DO interface: 1 way optocoupler output interface

Communication interface: 1-way RS485 (with isolation), standard MODBUS protocol

Power supply mode: DC 12V 100mA; power strip isolation

Working environment: temperature: 0 70℃,humidity: 0% - 95% non-condensable

Storage environment: temperature: no condensation at 5 ~30℃,humidity: 30~90 RH%